The end is in sight. Or at least it would be if the lights worked. Frank Westworth wrestles with Lucas…

Everyone hates wiring. Everyone hates electrics. I know this. I know this because I hate and fear anything electrical. At least … I used to hate electrics, but that has all changed now. I have become a better, more complete person. My life is more fulfilled, and nine-stone weaklings no longer kick sand in my face when I’m gliding the surf on the Fistral Beach. In short, as well as being a noted mechanical expert, I am now a similarly noted electrical expert. Strange, but true. And I shall explain how you too can become afraid no more of the mysteries of Uncle Joe. Lucas, that is, not Stalin.

Even the most short-sighted and optimistic of old bike enthusiasts (OK; that’s me!) would have understood immediately that a burned-out motorcycle is going to be unburdened by wiring. Flames and great heat remove plastic insulation faster than Ariel riders remove beer from bottles (and that is fast, RealClassicists!), leaving an entertaining tracery of copper strands festooning the carcase like corroded Christmas decorations or the webs of seriously macho metallic spiders. And where the heat has been greatest, those strands turn to little blobs, where the copper and solder and brass and everything else has melted, burned and solidified again. I looked at the photos from the fried National Motorcycle Museum and nodded sympathetically.

But as usual there is a bright side to this. As there was no wiring or switchgear or generating or igniting kit left on the Toastmaster, I was free to replace it all with pukka new kit. You cannot be accused of damaging a bike’s originality if there’s nowt there original to restore, rebuild or throw away in screaming disgust.

Sean CMES Hawker is my favourite electrical man. He’s rebuilt several hopeless electrical cases for me over the years, and as I’ve mentioned in an earlier instalment, he rebuilt both dynamo and magneto for me in a reasonable time and at a reasonable cost. He also makes dreadful drinks for his favoured customers. Telephoney and mail order services appeal a lot when faced with the awful coffee alternative…

Sean also supplied me with a wiring harness. I was wary of this, as I’ve had long and distressing experience with wiring harnesses, most recently with the harness for Rowena’s BSA B25SS, which was a complete mystery, and which could be interpreted in as many ways as a politician’s promise. It still doesn’t work properly, and the colours of the wires, although intriguing and a faintly interesting alternative to counting sheep if insomnia calls, still bear little resemblance to those depicted in the BSA manual. But the Ariel version was different.

The Ariel handbook version of the wiring diagram showed colours exactly like those on the new harness. And the harness came complete with a photocopy of the Ariel diagram, complete with an extra wire. This extra wire – or ‘lead’ as we experts call it – was an additional earth running from the headlamp nacelle assembly back to the main frame, showing that in this world there is at least one other person who understands that expecting a grease-packed steering head ball race to provide electrical continuity between the forks and the main frame is at best optimistic.

This was a good start. And I emailed the Mighty Men At Draganfly to provide me with all the other fripperies demanded by MoT inspectors before they’ll accept that a bike’s electrical gubbins are roadworthy. Things like a headlight (always useful), an ammeter, a dip and horn switch, a brake switch, a headlight switch, and other things. I already had an autojumble tail light assembly, so I

was well on my way.

All of my previous attempts at sorting a bike’s wiring had been largely unsuccessful. If, say, the lights didn’t work before I expended vast time, great effort and greater expense on fixing them, well then, the chances were that they still didn’t work when I’d finished. I once rewired a Matchless lightweight 350 single using a wiring diagram from An Acclaimed Expert who had a definite and lateral approach to such matters, including a lot of grave references to a ‘dropper wire’ which I believed proved him to be a genuine expert. That harness didn’t work at all, so I sold the bike to a number plate stripper, who somehow got it MoT’d, removed its already age-related number, applied another one, and shared in my amazement when the bike turned up at a Stafford auction boasting a new MoT (another one) and another new registration – and it still had no functional electrics, didn’t run and sold for an improbable sum to ‘a collector’. Collector of what, I didn’t ask.

But when I uncoiled the new loom for the Toastmaster, I was decently hopeful. The wires went where they should have done, and were all over-length by enough to make an allowance for my predictably poor soldering skills. But what’s this? I didn’t need to do soldering, because not only did all the wires go where they should, they ended in the correct connectors! This is all looking remarkably easy…

And easy it actually was. Because I don’t believe that anything really works, ever, I checked the continuity of every lead before I connected it (because I am hoping to become a genuine expert I use a meter rather than two bits of wire, a battery and a light bulb: meters cost about a fiver from any jumble) and every wire proved to be break-free. Every switch worked too. These meters are great things for fixing paranoid views of wiring. I was reminded however that none of the new bits were actually Joe Lucas bits; they were all replica Joe Lucas bits, which must be a worrying thought! But I am now an electrical expert, so I do not need to worry, of course.

Working with new parts is remarkable. All my memories of electrical disasters involve mysterious stickiness, ends of wires tied together and then blobbed with solder, Lucar and chocolate-block connectors which somehow always fall off, miles and miles and miles of sweaty insulating tape, some of it classic cloth-backed, but all of it horrid. And the end result was always a dim yellow glimmer or total darkness. I blamed Joe Lucas, as did we all…

However, in these strange days there is far, far greater spares availability than there ever was when I were a lad (sighs, puffs on pipe, etc), and lots of these parts fit properly and work properly, too. Lots, but not all of them.

I’d wrestled all the wiring into the headlamp (and yes sir, the Toastmaster boasts a genuine Ariel tin headlamp bowl, much to my surprise!). I’d fixed it all to a pattern ammeter, run a lead to the speedo light, lots more leads to the replica light switch and to the replica horn/dipswitch, and thought I’d try it all out. The sidelight works – hurrah! The ammeter shows a charge – hurrah! Hang on. The engine’s not running; how come the ammeter shows a charge? Swap leads over; ammeter shows a discharge – hurrah! That’s lots of hurrahs, you know; things were merry down in The Shed. Thor, King of Hammers, was feeling redundant, so I dropped him on my foot, just to make him happy. He was. My foot hurt. I drank fresh orange juice and swore a bit. Life was good.

I tried the (horrid repro but functional) horn. It issued forth a feebly indignant squeak – hurrah! I switched on the headlight. Nothing. This is more like it! I fiddled with leads. Nothing. Back to normal; sighs of relief all round.

Happy in my work, I replaced the 6v halogen headlamp bulb with another 6v halogen bulb. Switched on the lights. Nothing but darkness. This is what we expect; endless mysterious problems. I replace the 6v halogen headlight bulb with an ancient 6v tungsten bulb. It lights! Hurrah! I flick the dipswitch. There is a mysterious ‘pop’ and everything goes dark.

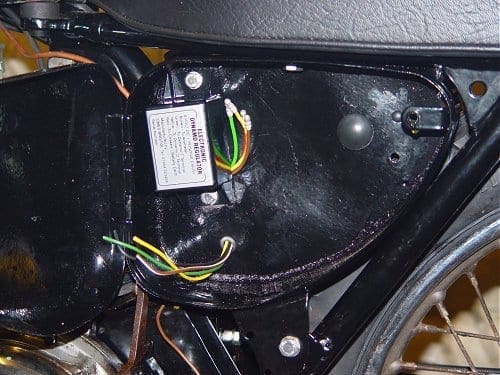

Meanwhile, down at the bike’s midriff, I have discovered that my super-duper CMES solid state regulator doesn’t quite fit the holes in the toolbox where the original Lucas electro-mechanical device may once have sat. I drill another hole, cheerily making a right mess of the super-hard plastic coating in the interests of great lights to come. None of the wires on the new regulator are coloured anything like the originals. Great confusion. Prepare stern mail for Sean; then realise that there’s a key to the colour coding stuck to the regulator. Herself points out that there’s also a sheet of instructions in the box. I feel appropriately sheepish.

Discover interesting little paper tags on the harness. Tags saying things like ‘Batt +ve’, and ‘R/B lt’. This is very exciting. I almost wish I’d saved all these little fiddly bits for the week between Christmas and New Year, when I get sated with mince pies and polite company.

I display stunning intelligence by understanding that the rear mudguard tailpiece is made of glassfibre, so the tail light will need an extra earth lead. I told you; expertise is looming.

Then I fit the tail light, bought earlier from a jumble stall. The mounting studs don’t fit the original Ariel number plate. I notice that the editor of the excellent Ariel OC’s magazine is selling a number plate on eBay, but forget to bid for it. I go to Kempton Park, hunting for a genuine Lucas rear light. No-one has one. Despair. Scratch head. Buy round file with the intention of enlarging the holes in the original number plate to fit the useless pattern light. Understand that this is insanity, and buy another, guaranteed to fit repro light assembly. Speak to Sean CMES Hawker at Kempton, who tells me that he rebuilds Lucas rear lights from old bits, but only for friends. I smile, winningly. Sean strolls off…

Get home; fit rear light. Do not ask questions at this point.

Lighting is all there, even the amusing Ariel well-hidden brake light switch. It all appears to work. All the bike needs for its MoT are a few final touches. This is a worry…