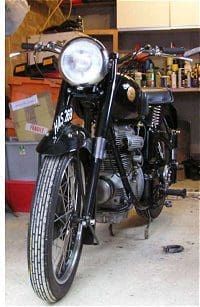

Steve The Toaster strips his P&J and finds that the inevitable has indeed come to pass… not only that, there is, indeed, no such thing as a quick fix. Next stop? The bank balance void…

There are many dangerous words in the English Language when it comes to buying secondhand motorcycles; one of the very deadliest is the verb ‘assume’.

One of the meanings given in my dictionary for this verb is ‘to take for granted’. This, in itself, is one of the biggest perils to motorcycle purchasing. The second one, in my case, even after I’d written several bike-buying guides, was not to take my own advice.

When I purchased my Sunbeam, I was delighted to have received a folder with a sheaf of papers in it, listing nearly every replaceable item within the confines of its shiny aluminium crankcase, as well as a good many outside. Notice here the careful use of the word ‘nearly’. The vast majority of the cycle parts were of ‘original manufacture’; the motor started with the greatest of ease, then ticked over and revved with a smoothness one could only dream of on a fifty year-old twin, and would rival many modern 500 twins, especially those of, shall we say, European manufacture?

As this is part three of an article which I never ever intended to have to write, you’ll be well aware (from part 1 and part 2) of the oil leak that began in earnest on the S8’s maiden voyage. With help from Emm and a fine band of RealClassicists, I removed the engine and gearbox as a unit. It was now time to strip these two main components apart and continue into the dank, dark, oily depths of the innards to find the source of the leak and bring about an effective, swift and above all, inexpensive cure to its wanton lubrication of Her Majesty’s finest blacktop.

Did I dare to say swift and inexpensive?

Oh dear, I can hear the snurking from the back of the room from here. (Snurking is that nasal squirting noise people make when they read, or hear, something that immediately strikes them as ridiculous, or maybe just fanciful, but they feel embarrassed about howling out loud). However unfortunate it is, this just may turn out to be incredibly prophetic snurking.

The gearbox, complete with its car-like built-in bell housing, was removed from the crankcase with alarming ease; one main feature of the bike so far having been that nothing was done up very tight. The ‘Hungarian mechanic’ (two words that now strike fear into me and send shivers down my cheque book) the former owner had used to rebuild this engine must have stripped many threads in his early days as he obviously had a phobia about tightening things up on this ‘Beam. Next on the list was the clutch – again, the nuts all popped off OK and the huge flywheel centre nut was no problem (despite the thread lock that was evident), thanks to the loan of the correct size box spanner from a similarly addicted Sunbeam enthusiast. The amount of oil in the bell housing was also significantly in line with a previous diagnosis that the rear main crankshaft oil seal had given up the ghost.

Once free of the flywheel, the rear tin-plate engine back-plate which houses the oil seal becomes available. Lurking in this flimsy, and almost legendarily unsealable item, is the offending rear main oil seal. Ah, I hear you claim, the job’s that easy. Silly me, I thought so too, at this point. Removing the plate was easier than stealing the last roasted shallot from Emm’s dinner plate, and caused me almost as much trouble afterwards.

Holding the plate in my hands, the crack (yes, crack) in the lip of the seal became plainly evident. The seal was rock hard, and was virtually impossible to move in any direction. Fifty years of heating and cooling, as well as exposure to oil, had hardened it to a consistency of china and rendered it as easily fractured. The seal was not worn out, the surface of the crank where it runs was not marked; it had simply become so hard that it just cracked, chipping a piece the size of a pea almost right off. Rubber components, in such a hostile environment, can only last for so long.

At this point I had been fairly cock-a-hoop. I’d not only correctly diagnosed the trouble but thought myself to be facing a cure which was simple, moderately inexpensive and, subject to the availability of the seal, quick as well. I could almost have leapt in the air and clicked my heels together. The watchword here is ‘almost’. Oh, ridiculously hopeful, foolish, if somewhat kindly, greying, middle-aged man.

On the advice of the other ‘Beam owner, I checked the ‘half-time’ wheel and its mounting pin for play. This wheel, actually a gear, is driven by another gear exactly half its size on the rear of the crank, and runs, unsurprisingly, at half crank speed and then by use of a short chain it turns the over-head camshaft. It is pressure fed from the same oil supply that feeds the crankshaft, and any play in its bush can cause low oil pressure in the crank itself. Wear, as in slop, from side to side, indicates that the bush in the gear needs re-bushing and subsequent reaming, and so it was removed for inspection.

On the advice of the other ‘Beam owner, I checked the ‘half-time’ wheel and its mounting pin for play. This wheel, actually a gear, is driven by another gear exactly half its size on the rear of the crank, and runs, unsurprisingly, at half crank speed and then by use of a short chain it turns the over-head camshaft. It is pressure fed from the same oil supply that feeds the crankshaft, and any play in its bush can cause low oil pressure in the crank itself. Wear, as in slop, from side to side, indicates that the bush in the gear needs re-bushing and subsequent reaming, and so it was removed for inspection.

As you will have guessed, it showed signs of wear also. Bugger.

OK, so the inner rear engine plate, which supports the rear of the crank by way of the rear main bearing, also has to come off as the half-time pin is a press-fit in this plate, and a new pin will have to be made, hardened, ground, and pressed in and have the gear end-float set up. No big deal, I thought — off with all the camshaft drive gubbins, rear crank gear, and after cobbling together a puller at the suggestion of local friend and BritBike aficionado, Will C (remove your cap, take a bow and tug your forelock. Oh, you can’t…), the inner back plate finally came off.

At this point Will, in a valiant attempt to save me trouble later, pointed out that the rear main bearing had flaked, so that will need replacing too. It’s located in the inner back plate anyway, so no big deal there as it’s going into the machine shop for the pin to be pressed out for replacement.

I hypothesized that if the rear main oil seal was the original, then there was a jolly good chance that the front was too. If the moron, sorry, Hungarian mechanic who rebuilt this engine with loads of new bearings and sundry parts didn’t have the gumption to fit a new rear seal, there’s an odds-on chance that said moron didn’t replace the front either. Bugger again, I thought. Well, by now, there’s only the head, pistons, con rods and armature left attached, so we might as well… Oh, dear, there goes ‘swift and inexpensive’ right out the window. The ‘extra snurking’ queue line starts here.

First up, the armature on the front of the crankshaft. ‘Remove the left-hand threaded centre bolt, and simply pull off ‘ I was informed by Stewart Engineering’s ‘Bedtime Book’ (the tome written by Stewarts for owners of S7s and S8s). Hmm. ‘Simply’ was the key word here – nothing had been simple so far and I did not expect the armature to co-operate in any way, shape or form; I was not to be disappointed either. Liberal doses of Plusgas, swearing, offers of a good night out, blatant crying, throwing teddy out the pram, stamping of feet, etc, would entice it to come off. In the end, brute force and ignorance won the day. If anybody should happen to have a serviceable armature, my address is…

My friend, the ‘Beam owner, thought that we may be able to push the pistons and conrods up the bore, having removed the end-caps from the big-end bearings, thus allowing enough clearance to withdraw the crank, leaving the cylinder head attached. (I pause for a big, big sigh here. I’m sure you’ll understand why).

My friend, the ‘Beam owner, thought that we may be able to push the pistons and conrods up the bore, having removed the end-caps from the big-end bearings, thus allowing enough clearance to withdraw the crank, leaving the cylinder head attached. (I pause for a big, big sigh here. I’m sure you’ll understand why).

Therefore, once the cylinder head was removed, the pistons and rods should have popped out the top of the cylinders. One did, one didn’t, but we managed to wiggle the crank out anyway. After much faffing about, the offending piston and conrod was withdrawn from the bottom, to reveal a burr on the edge of the top of the conrod so tiny as to be almost impossible to see – even with my glasses on — but enough to stop it popping up the bore.

Dear reader, would you be surprised to know that front roller main bearing was also the original one? On once again consulting the ‘Bedtime Book’, it appears that the original ‘ball’ type was prone to collapse, and should never be refitted. Instead, a ‘roller’ type should be substituted instead, and it would seem (further?) madness not to have the sludge trap cleaned out at the same time. I feel quite sure that fifty years will have easily been more than long enough, for a suitable amount of sludge to have gathered in the trap, and the chances of the previous ‘Hungarian mechanic’ bothering to clean it our are, well, what are the odds of winning the national lottery? Uh huh, about the same.

The front seal, on inspection, was indeed rock hard, although it had not yet cracked, but somehow, I think I will be replacing the little darling while the opportunity is there. It was no surprise to find that the ‘new’ crank big-end bearings, listed in the ‘sheaf of invoices’ I received with the bike, were all marked. This is possibly due to the reduced oil pressure caused by the worn half-time wheel and pin, as well as the massive loss of oil, so I will have to replace these at the same time. The upshot of this will be all new crank bearings from front to back, hopefully eliminating all of these problems.

Well, there it is – stripped very nearly to its component pieces, almost every last one. Only the camshaft remains attached to the head, and I can think of no good reason to disturb that little darling. You have one? Unsurprisingly, I seem to be suffering from selective deafness. I wrote out a list of re-engineering requirements, and of parts needed to facilitate the rebuild, which runs to two pages, and is worryingly expensive-looking. I delivered the parts that need fettling in a machine-shop type environment to Stewarts, the only Sunbeam specialist around, where a very nice man known as David looked over my oily parts. He pointed out that the rear crank bearing surface, which, you may remember, was originally mated to the flaked bearing in the rear engine plate, had indeed got a lip on it (although no where near as big as mine at this point I might add) and would require turning down to the next available bearing size.

Well, there it is – stripped very nearly to its component pieces, almost every last one. Only the camshaft remains attached to the head, and I can think of no good reason to disturb that little darling. You have one? Unsurprisingly, I seem to be suffering from selective deafness. I wrote out a list of re-engineering requirements, and of parts needed to facilitate the rebuild, which runs to two pages, and is worryingly expensive-looking. I delivered the parts that need fettling in a machine-shop type environment to Stewarts, the only Sunbeam specialist around, where a very nice man known as David looked over my oily parts. He pointed out that the rear crank bearing surface, which, you may remember, was originally mated to the flaked bearing in the rear engine plate, had indeed got a lip on it (although no where near as big as mine at this point I might add) and would require turning down to the next available bearing size.

Predictably, my only comment was… Bugger.

The one piece of good news was that the half-time pin had already been machined (Stewarts have many odd parts manufactured themselves) and has gone off for hardening, hopefully reducing to about two weeks my wait for all and sundry to be done. Then I will be able to go and collect everything and rush home to expend much midnight oil in the re-assembly of my ‘darling little twin’, (which I’ve only had one ride on, although it was great fun, despite having to stop and replenish the pathetic three pint sump every once in a while).

However, now I have it disassembled, and I have taken advice from those with Sunbeam know-how, I will take no prisoners this time, and the engine WILL be carefully assembled with all the right parts and sealants and will then be run in accordingly. I have also been given a clutch release mechanism modification by my new ‘Beaming Friend’ (also take a bow AJSBSA, oh fountain of S8 knowledge and folklore, as well as lender of specialist tools), which will reduce the incredible amount of strength required to release the clutch to a girlie amount that even my knackered left arm can cope with. My ‘Beam will be jolly fine to ride, as it putters along next to Olive the recalcitrant Enfield to all manner of shows and events this year, with a large, long-haired person aboard, grinning inanely. That’ll be me, then.

My main mistake in all this was down to the English language, or at least, my failing to fully comprehend its usage and the nuances of it. My English teacher would not be in the least bit surprised, so that hopefully it makes some kind of sense for you. It’s that word, ‘assume’, you see. I naturally assumed that anyone who would rebuild an engine with new bearings would logically use all new oil seals, not fifty year old ones. As Captain. Mainwaring would have said; ‘You stupid boy’, and he would, without doubt, have been spot on.

Blown a seal?