The Power Behind The Bang Behind The Clutch Behind The Rear Tyre… Dave Minton explains about sparks…

You may have grasped that I have, through probably crack brained deliberations, become the owner of a Velocette Venom. As to the reason why, rather than repeat myself or leave insufficient opportunity for further tales of the drive towards yet further masochism, I ask only that you take my choice on trust.

Apart from the final year or so of production, which was shameful, Velocettes upheld the finest traditions of the old British motorcycle industry. By the mid-1960s Hall Green’s ohv singles reflected in their angular construction the values of a much earlier age. Through their performance however, could we not perceive what extraordinary heights those values achieved? That lovely ‘square’ dimensioned engine, a throwback to the 250cc MOV of 1933, would over a long run over mixed roads best almost any 500 twin of the period that cared to chance its arm, and a good many 650s besides.

From my period point of view however, Venoms and their ilk suffer from one drawback: they demand meticulous attention to the routine of kick-starting. The preciseness of one’s genuflections need to be exaggerated beyond say a G80’s or B33’s chummy co-operation if one’s Venom is to thud into life. Four years with an MSS imprinted itself indelibly into my consciousness. This has nothing to do with a slap-happy combustion chamber. Nor is it, as Velo Fellows love to imply, the consequence of atrophied manhood.

The plain fact is that, for reasons I do not fully understand, Velocettes are equipped with undergeared kickstarters. The advantage of this lies in the comparative ease with which combined leg muscle and flywheel inertia bumps the engine through compression and, hopefully, starts it. The disadvantage is twofold. 1: engine speed is unavoidably low during kick starting. 2: In order for the piston to travel through the combustion stroke it has first to be placed static along its stroke with rare precision to maximise piston speed and the variously related factors contributing to the combustion stroke: these are carburation, incorporating combustion gas swirl and tumble, and ignition. Were the kickstarter pedal crank not so short then perhaps through the increased leverage gearing could be raised? Be that as it may, in decent tune a Venom in the hands of a doting owner proud of his thoroughbred’s spirited heritage will fire up with the best of them.

Mine, of course, did not. Its carburettor settings were suspect and its spark was too.

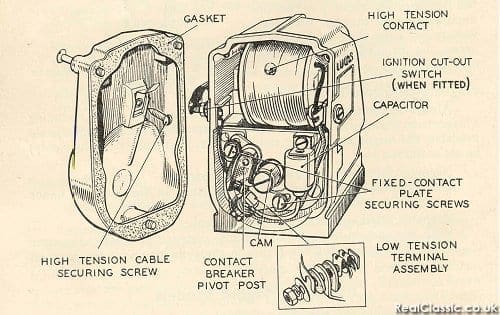

Lucas Magneto

As my Velo mentor, ex-racer, professional expert and spares stockist Nick Payton (020 8540 2118) surmised over the phone after listening to my tale of grief, wounded pride and descriptions of an engine refusing to pull top gear; ‘Sounds like the mag’.

Out of my 40 years muckin’ about with old motorbikes one wisdom has risen above all others. The golden rule is, unless you are convinced deep in your very soul that the mag is ticketyboo, don’t waste your time fiddling with anything else. A weak yet reliable spark will mislead you through apparent poor carburation into more grief than you can possibly imagine, while a strong yet irregular spark will convince you that malevolent hobgoblins inhabit the entire power train.

Because Britain is no longer a manufacturing nation (thanks be to successions of governments run by selfserving academics bereft of vision and courage) it yet retains a terrific reservoir of ex-manufacturing engineers. Many of these have retired from industry yet remain active in their old spheres as self-employed craftsmen. One of them is Bryan Simmons (01746 712193) who lives a lively 30 minute ride through the hills from me. So I gave him the Venom’s Lucas K1F mag for a total rebuild.

[Right] Lucas MN2 magdyno on a 1939 Triumph twin again. It fits very snugly beneath Mr Amal’s carb. An unusual sight these days.

In the tradition of the best craftsmen, Bryan has retained his sanity over the years by adopting light cynicism. I handed over my carefully packaged, precious K1F. ‘Nice and shiny anyway,’ commented its future saviour before placing it on his work bench with barely a glance. We had previously discussed other manufacturers and I professed ignorance over their supposed superiority. I was shown two others. ‘This one is a BTH and it’s much better made. And this one is a 1912 Bosch and it’s even better.’

At this post-technical point we will put the magneto into perspective by travelling backwards a century. The four great evolutionary steps in the history of cars and motorcycles are the High Tension magneto (1905) the plate clutch (1919-ish), the wire beaded tyre (1927), and shortly thereafter the stabilising of the combustion process by the addition of lead to fuel. The latter three are of necessity subservient to the magneto because uniquely among the four the HT mag provided foundation reliability rather than refinement.

Bosch Magneto

In fact Robert Bosch did not invent the HT magneto. Frederick Simms, an exceptionally gifted Englishman, had by 1897 patented a Low Tension magneto (unused on motorcycles), manufactured for him by Bosch. Following that, a variety of experimental HT mags were produced, mainly in France. The best of them, from the Boudeville company, was further developed and manufactured by Bosch, which adopted by agreement the Boudeville system for its own. As a matter of commercial significance, to this day the mighty Bosch industrial conglomerate continues to employ the cross-section of a stylised magneto as the company trade mark.

Until the introduction of the HT magneto, the almost universal yet wretchedly puny four volt LT coil and contact breaker ignition systems employed on motorcycles caused deep despair. Even motorcycling’s staunchest advocates admitted that so much of the pernicious unreliability then endemic was ignition-originated and came to within a whisker of plunging the infant industry into the abyss.

Almost parallel with the HT magneto came the HT coil and contact breaker (c/b) system from Delco in the USA. This was much cheaper to produce than a magneto but it had innumerable disadvantages for motorcycle use. It relied on a 6v battery, or accumulator as they were popularly known, which then were untrustworthy yet expensive things vulnerable to the vibratory hammerings of rude engines and solid frames. This was furthered by motorcycles’ weak little dynamos producing insufficient power to cope usefully with lights and battery charging. Advantageously a magneto’s spark above 3000rpm was usefully more intense in dealing with the higher compression ratios of motorcycle engines, although at ultra low engine speed the HT coil spark was the stronger. Disadvantageously, as Velo owners like myself know, magnetos do not volunteer much of a spark at very low, ie. kickstarting, speed.

|

I will run lightly over the operation of a magneto. In construction it consists primarily of a permanent powerful magnet. The magnet is secured immediately outside the axis of an armature, which incorporates powerful field windings. As the armature rotates through the magnet’s field, an electric current equating to around 30 volts and five amperes is generated in the primary coils. When the primary current is broken at maximum flux by the opening contact breaker points a powerful current is triggered in the secondary coils wound over the primary. It is this that generates between 12,000 and 15,000 volt sparks, depending on model, across the plug’s electrodes. Why does not the full charge of the current crack across the tiny gap of the open c/b points? Because a condenser is parallel-fitted into the circuit to store the current until the HT lead’s pick up brush and the revolving slip ring’s brass contact segment make contact. If you wish to investigate the full technical details of the magneto’s history you are advised to read Bryan Simmons’ two valuable contributions to the VMCC magazines of December 1998 and February 2002. His experience with and knowledge of magnetos is probably unrivalled in Britain. A fully qualified electrical/mechanical engineer, Bryan began the repair and rewinding of armatures in 1946 and by 1975 was concentrating solely on the repair and re-engineering of magnetos. These came from industry, vehicles of all types and periods, and historic aircraft. He is a lifetime motorcycle enthusiast with a penchant for AMC singles, of which he has owned a small handful, all of which he has rebuilt to as-new specification. During my motorcycling apprenticeship in the Fifties and the wilder times of the Sixties, friends and I mercilessly thraped Tigers, Goldies, Dommies, Rockets, Connies, Shadows and the like the length and breadth of Britain. We quickly grew to despise Lucas’ nightmarish early AC electrics, now made reliable with modern know-how, but we found little to criticise in Lucas’ magnetos. So long as they were made watertight and their slip rings, brushes, c/b points and HT pick-ups checked occasionally, they performed admirably. They even worked when they should not, as a pal’s BSA A10 RR proved when on arrival home after a 170 mile blast from North Wales oil was found pouring from the c/b point housing. The drive end oil seal had broken up and the whole instrument was flooded, without apparent loss of performance! Despite that, we yearned for a superior BTH mag, as seen on a rare competition Trumpet, and once or twice we would stumble across a Bosch that someone had fitted to a KSS Velo or a Rudge. Two of us then bought Vins and almost immediately learned from older Vincenteers of the profound superiority of the mythical Swiss-made Scintilla instrument. Nobody knew precisely why Scintillas were better, nobody we ever met had ever seen one, let alone ridden atop one. For all our lack of practical experience, however, the popular lore of magneto meritocracy was for us cast in concrete, and in retrospect our belief was probably not far out. Innocent of the mysteries of magneto quality after a half century’s rumination, I asked my expert near-neighbour to explain. Bryan emphasised the need to judge Lucas’ standards by commercial requirements. They were of necessity built surprisingly well to meet a low cost demand. BSA, for example, may have demanded 20,000 K2Fs at no more than, say, £3 each, and for the sake of its survival Lucas would comply. One may, of course, query the wisdom of such a policy in the light of Bosch’s rise to commercial pre-eminence. |

Magneto stuff on eBay

The Bosch trade mark; a magneto armature. The German company is all too aware of its origins. |

When the Great War of 1914-18 began, Britain was more-or-less bereft of large scale magneto producers, having lost the Bosch supply of course. The industrio-politics involved are too convoluted to report here but the British Government was desperate for high volumes of magnetos to reliably fire up the burgeoning aircraft industry’s military products in particular. As a consequence it strongly encouraged (probably with contractual incentives) the breaking of foreign (Bosch) patents and the consolidation of a litter of approximately 17 small-scale British magneto makers into a much larger commercial enterprise. 33 existed abroad.

By the 1920s two British companies had absorbed most of their smaller UK rivals. These were Lucas, whose core production was for the auto-industry, and the electro-mechanical giant, British Thompson Houston (BTH). When comparing the two makes respect must be paid to the fact that Lucas’s aircraft magnetos, in being forced to match aviation’s rigorous demands, were the equal of any. The auto-industry’s requirements were quite different: a motorcycle’s or car’s occupants anticipated neither death nor injury on the loss of ignition, merely inconvenience. So with competition from continental Europe and the USA, Lucas was forced by production cost to compromise. As auto-magneto production was little more than a sideline for BTH and as most of its magnetos were destined for the higher planes of industry and aircraft, its motorcycle instruments could hardly demonstrate compromise.

By the 1930s the familiar magneto was approaching a plateau of efficiency, beyond which it has not much advanced since. A combination of technical improvements to permanent magnets by the use of much harder steels from the Eclipse Co of Sheffield (yes — the saw and cutting tool makers), finer wire-drawing techniques for armatures and improved aluminium and other alloy casting techniques, eventually contributed to a much more compact and reliable spark engine.

In the late 1940s AMC listed a Lucas mag in its spares list at £7, 17s, little more than Triumph’s £7, 10s for a mag in 1937, but most motorcycle manufacturers of any sporting pretension listed a BTH mag’ as a £5 alternative to a Lucas item. If one considers that, for instance, my own T100 was listed at £87 in 1939, this reflects an extra 4.3%. But who would need the stamina of a BTH mag without also the bronze competition cylinder head at £5? Thus, we have an extra 8.6% (£10) on the price of a super sportster now selling for £97. £5 in those times was a week’s wages for a skilled artisan.

What then, is the difference between a BTH and a Lucas magneto? Of necessity armatures need fabrication in non-magnetic metal. Unsurprisingly, as it was a world pioneer of high grade brass casting, Lucas employed brass.

The ubiquitous Lucas K2F twin magneto.

As time passed and engine speed rose it realised that brass bearing spindles were inadequate, so it cast steel spindles into the armature body. Idealistic BTH side-stepped brass altogether by manufacturing the flexure-vulnerable ends of its armatures wholly in stainless steel, that were then flange-bolted to the armature core. As a consequence BTHs were altogether more robust and durable instruments. In common with the majority of British motorcycle factories in the post-WW2 period, AMC employed Lucas electrical equipment. By 1949 AJS had so well finished the development of its near-flat 500cc parallel twin ‘Porcupine’ racer that it contested the IoM Senior TT, which at that time enjoyed unalloyed fame as the world’s most prestigious motorcycle event. Les Graham, one of the greatest road racers of this or any other period, was given the responsibility of the new works Ajay. Until the last lap he was leading (though Bob Foster on a Guzzi actually achieved the fastest lap at 89.75mph) but then the Porcupine’s engine stopped dead at Hillberry. A works Manx with Harold Daniel at the helm took over the lead and that was that.

A speedy analysis of cause by Matt Wright, AMC’s race development engineer, revealed all too clearly a sheared magneto spindle. Furious, AMC demanded that Lucas provide it with magnetos equipped with BTH-type armatures, rather than items reliant on stub spindles cast into the armature’s brass body. Lucas retreated behind explanations of the impossibility of such engineering. AMC threatened in all seriousness to transfer its entire electrical purchasing contracts to BTH and Miller. Lucas, unsurprisingly, delivered new race mags to AMC’s specification within a couple of weeks. Not in practice that this much helped the powerful (45bhp-plus, 120mph) twin-cam Porcupine, which despite a terrific series of wins on the Continent proved to be unrewardingly techy and was retired in 1954.

Typical Lucas mag armature. This is an early one with one brass spindle and one cast-in steel spindle, a specification satisfactory only with slow-revving engines.

As far as we are concerned with our roadsters, for which Lucas armature spindle design is perfectly adequate, the biggest problem lies in the failure of sparks in rarely used magnetos. This is not usually due to a loss of magnetism in the permanent magnets, as so commonly believed. By the mid-1930s both Lucas and BTH were relying on magnets made from a newly developed steel alloy registered as ALNICO (a nickel/cobalt steel alloy) and it required no keeper to hold its magnetism.

Loss of sparks is commonly rooted in armature winding failure, most especially on machines stored unused for long periods, and most commonly when storage conditions are not completely dry. As Brian Simmons’ experiences have revealed, a 20 year-old brand new Lucas armature left on the shelf within its original wrapping can, and will, fail in use. In all probability a BTH will not.

Lucas MN2 magdyno on a 1939 Triumph twin. These remain unusual because once twins became popular in the post-WW2 period the separate K2F mag was preferred, and rightly so.

Lucas wound its armatures with fine wire of around 00.002/3 inch (0.0508/0.076mm) interleaved with 00.001 inch (0.25mm) insulating paper. Once fully wound the whole would be heat and/or vacuum varnish sealed. BTH tended to use a finer wire with each winding insulated by a layer of varnished silk. Moreover, where Lucas condensers relied on paper in their construction, BTH used Mica.

As Bryan observed in his own VMCC writings, ‘A BTH winding will always outlast a Lucas.’ And Titch Allen remarked in the same piece over a 40 year old Lucas mag: ‘It may be difficult to put a life on a winding but an (long-time) unused Lucas will almost certainly fail the first time it gets warm, and a WW2 BTH will still be sound of wind and limb.’

A covertly impressive example of BTH’s ideals and Lucas’ commercial-inspired compromises is revealed in the rising engine revs of the later 1920s and early 1930s, especially with the advent of cammy engines: contact breaker points began to bounce, wreaking mischief. Whereas Lucas simply increased c/b point return spring strength, BTH, after systematic research, lightened the c/b rocker arm. Think about it: Lucas’s method actually increased stresses while BTH’s decreased them.

Lucas K1F magneto as used on all but a few post-WW2 AMC singles, which relied on the superior rotating magnet instrument.

If you plan to store your vintage or classic machine for long periods, say beyond six months, and your garage is not as dry as your living room, it may well pay you to remove the magneto and keep it in the house. Alternatively, after a longish run when the magneto is hot, wrap it in a few layers of towelling; 24 hours later to avoid condensation damage, pull a plastic bag containing a few sachets of silica gel over the towelling, and seal the bag’s neck with rubber bands.

Are magnetos rebuilt with modern technology superior to their ex-works condition? Bryan is none-too sure, although I felt that this response was as much a measure of the man’s modesty as reality. He reluctantly admitted after much prompting that his windings may be better than Lucas’ originals because of the higher standards he works to – the very best wire interleaved with superior resin-impregnated paper, the fitment of BTH-quality condensers and his meticulous assembly methods.

A measure of a modern magneto’s resistance to failure may be gauged by the fact that following their reconstruction, so as to harden their internal varnishes and exterior enamelling Brian has them baked at 150 deg C and they work perfectly.

You may be as confounded as I was to learn that a standard K2F armature windings contain an astonishing 1400 yards (1281 metres) of 0.002 inch copper wire and that, as us kickstarting loyalists will know, amounts to just under one mile (just over one kilometre). Watching a man solder a length of this to the heavier primary winding, when it shows up as little more than a shimmering spinneret, is to realise that craftsmanship is still alive and well in Britain.

Demonstrating that so many people, even the most professional, all too often overlook the vital role played by the magneto, Bryan told me a few tales demonstrating the strange innocence, even calculated ignorance, of mechanical engineers towards the vital combustion igniters of their charges. Tales of priceless historic aircraft almost crashing after years of otherwise meticulous construction, of cars worth mi££ions abandoned in the remoter places of this world were related with a wry smile. To avoid embarrassment I promised to identify no specifics. You must remember that, while a motorcycle enthusiast, most of his professional life until recent retirement was filled with much bigger stuff — racing cars, marine engines and aircraft. But such stories are typical of an old mag’s breakdown. So be warned. It may well spark when cold but after half-an-hour as heat builds up, that’s when the trouble so often starts.

Illustrations by Dave Minton, and the RealClassic Archive

This article was originally published in RealClassic magazine, which is only available by subscription. You can order a single back issue of the magazine here or an older one here, but they’re selling out fast…